You want to reduce your unit costs and implement the zero-error strategy in your company!

Our M.A.i robot control and pack cell is universal.

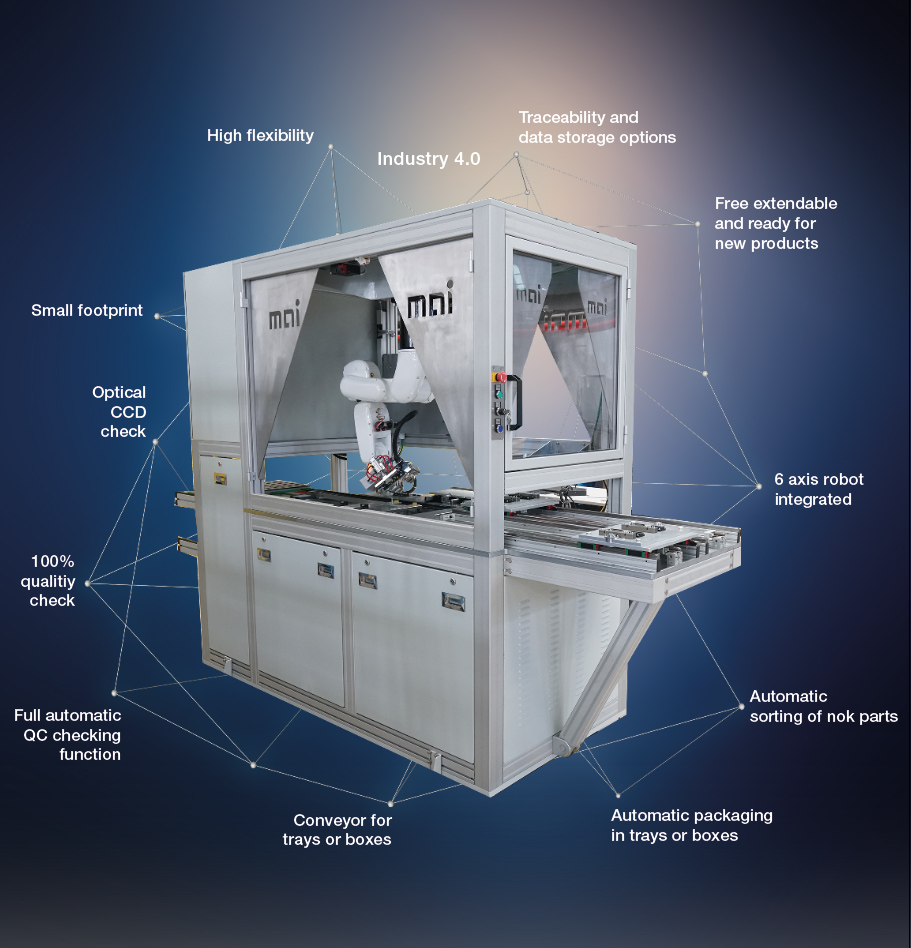

The automation module consists of the following characteristics and advantages:

– Adopt flexible production line design, compatible with multiple products

– Can be moved to different injection molding

machines for supporting production

– Save labor cost and improve labor efficiency

– Efficient visual inspection of product quality defects to achieve product quality. Full inspection and automatic classification of qualified /

unqualified products

– Qualified products are automatically pack into trays / cartons

– Product data storage and traceability, MES

communication interface

– Fully automatic / semi-automatic operation mode can be switched

Convince yourself!

您希望降低制造成本吗?您想实现产品的质量全面控制吗?您想提高产能吗?

我们的 M.A.i 机器人自动检测和包装单元是通用

的自动化模组,由以下几大特性和优势:

– 采用柔性产线设计,兼容多种产品共线

– 可移动到不同的注塑机进行配套生产

– 节省人工成本,提高人工效率

– 高效的视觉检测产品质量缺陷,实现产品质量

全检,并将合格/不合格品自动分类

– 合格产品自动包装到成品盒/箱

– 产品数据储存和追溯, 和MES 通讯接口

– 全自动/半自动运行模式可切换

Convince yourself!

技术参数:

尺寸L*W*H: 2.2m*1.2m*2m

自动化循环周期:

取决于产品的尺寸,不含检测时大约3-6秒/个

– 视觉检测约0.5 – 1秒

– 根据质量要求,可同时检测产品多个尺寸或

外观的要求

基本设备:

– 可移动式的主站,含LED 照明

– 最大的包装塑料托盘尺寸

400mm x 300mm 到 800mm x 600mm

– 加固式铝型材框架/焊接框架和喷塑钣金

– 气缸线性移动轴+载座底座

– 六轴机器人

– 视觉系统通讯接口

– PVC 成品输送带(1500mm*600mm)

– 西门子PLC,15.6 英寸彩色触摸显示屏,集成式电柜

– QC 滑槽/水口滑槽/废品滑槽

选项可扩展的系统功能:

– 可扩展并集成注塑产品取出模组

– 可扩展并集成托盘自动堆叠包装模组

– 数据储存和追溯

– DMC激光打码或贴标

– 洁净室等级要求

– 嵌件供料和植入模内注塑

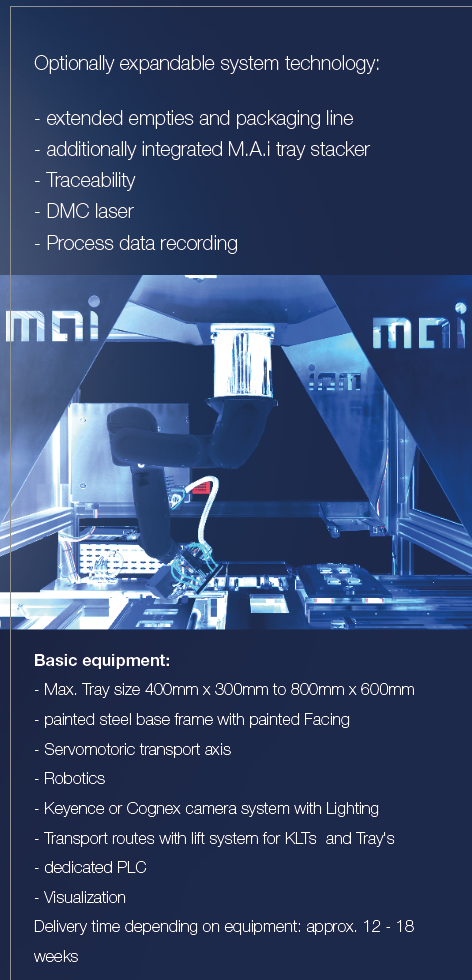

TECHNICAL SPECIFICATIONS:

– Size L * W * H: 2.2m * 1.2m * 2m

– Automated cycle:

Depending on the size of the product, about

3-6 seconds / piece without inspection

– Visual inspection about 0.5 – 1 second

– According to quality requirements, multiple

sizes of products can be checked

simultaneously or appearance requirements

Basic equipment:

– Movable main station with LED lighting

– Max. Tray size 400mm x 300mm to 800mm x 600mm

– Painted steel base frame/aluminum frame with

painted facing

– Pneumatic transport axis + carrier base plate

– Robotic

– Camera interface

– Conveyor with PVC belt (1500mm*600mm)

– Siemens PLC, 15.6-inch color touch display,

integrated electric cabinet

– QC Chute / Sprue chute / NG chute

Optionally expandable system technology:

– Expandable and integrated injection product load & unload module

– Expandable and integrated tray automatic stacking & packaging module

– Data storage and traceability

– DMC laser coding or labeling

– Clean room class requirements

– Insert feeding and over molding